BRAND NEW DESIGN

Stop Digging replaces the concrete

block with a modern foundation

– the ground screw

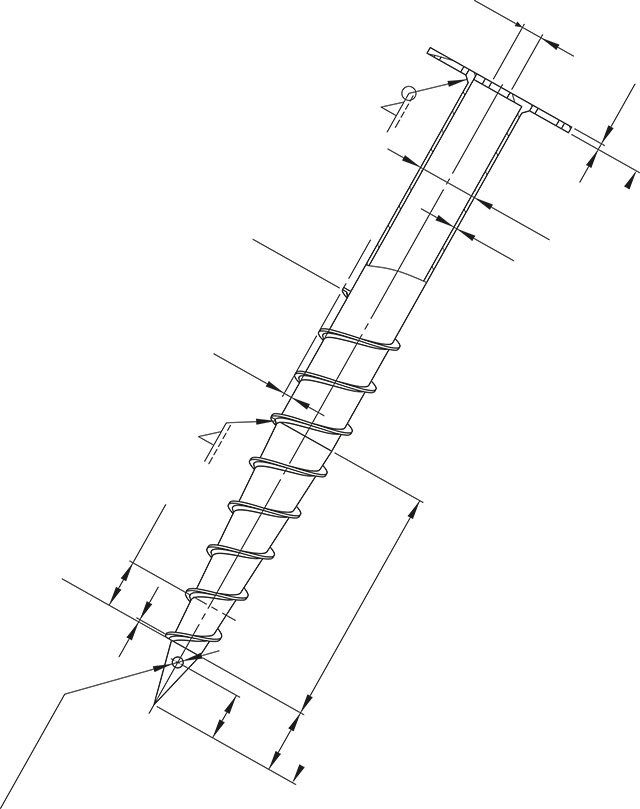

The Swedish company Stop Digging has developed the ground screw, an innovative method of ground anchoring without the need for cumbersome concrete foundations. Our ground screw offers a complete solution for a wide range of construction projects of all sizes and in all terrain types across the U.S.

We have designed and developed a series of ground screws to provide your project with a secure and stable foundation whatever the terrain or soil type you face. Furthermore, our screws are ideally suited to demanding tasks on uneven or difficult to reach ground, providing tailored solutions for flagpoles, solar panels and other uncommon installations. All of our high quality groundscrews are designed to exceed the requirements of the building code.

Stop Digging’s galvanized steel ground screws are specially adapted to cope with harsh environmental conditions. To assure a perfect performance, all our CE marked products are manufactured in ISO certified production facilities. Each ground screw model is thoroughly tested to meet our stringent load, pressure and tension bearing requirements, and exceeds the requirements of the building code for durability. Stop Digging and our installers are also ISO 9001: 2015 certified as an added mark of our professional standard.

PROFESSIONAL INSTALLERS

To meet this ISO 9001 standard, Stop Digging’s installers undergo rigorous training to use our specialised equipment and to have the right skills and understanding to offer our clients the best solution for their needs. Additionally, all of our installers carry full, public liability insurance. Our business ethos is not only to provide a high quality product, but to deliver and install it to the highest professional standard.

VERSATILE FUNCTIONALITY

Tailored solutions for every occasion

Whether it is for a small task at home or a large business project, Stop Digging’s ground screws can work for you. We have a wide range of experience in delivering many different projects for both private and public clients. This includes schemes ranging from simple parking signs to farm fences and from installing house decks to larger undertakings such as underpinning the extension of a historic cob and stone house.

Stop Digging’s ground screws are also ideal for temporary structures as they can easily be unscrewed and reused without damaging the ground, for example for fences at sporting events and festivals or for barriers and work sheds on construction sites.

We offer several different models and sizes such as the adapter, pipe, post and beam screw, all designed to tackle tricky terrain and soils. Our customers have used ground screws for lockups, storage rooms, bicycle sheds, recycling stations, sound dampening panels and traffic signs. The question isn’t when you can use a ground screw, but when you can you not?

APPLICATIONS FOR GROUND SCREW:

| B | I | J | K | L |

Decking and other platforms |

House and Cabin Foundations |

Enclosures, fences and barriers |

Park seating |

Flagpoles |

APPLICATIONS FOR GROUND SCREW:

B |

I |

J |

Decking and other platforms |

Recycling stations |

Enclosures, fences and barriers |

K |

L |

Park seating |

Flagpoles |

AUGER ADVANTAGES

Stop Digging’s screws are quick to use and cost effective

By choosing a ground screw, you avoid the hassle of digging and pouring concrete foundations and then wasting time waiting for it to set! The entire process for installing a ground screw takes only a few minutes and you can start using them immediately. With a fast and functional installation you save both time and money and keep your customers happy.

Our ground screws can be mounted in a wide variety of terrain, all year round, come rain, wind or shine. There is no need to postpone work even for a hard frost, as the ground is pre-drilled for each screw to ensure the best possible fixing. Our authorised installers are also experienced with anchoring soundly and securely in everything from sandy soil to rocky ground.

Our ground screws are also environmentally friendly in every way. They produce less carbon than an equivalent concrete foundation, cause less disruption to the ground, and require less plant machinery for digging. Furthermore, our screws are an excellent anchor for temporary buildings and other short term installations as they leave a minimal trace when they are removed. Our dedicated installers can also fix ground screws in hard to reach locations or confined spaces where digging and pouring concrete foundations is just not possible.

ENVIRONMENTAL SUSTAINABILITY

Changing the construction world’s climate impact

Today, the manufacture, transportation and use of concrete accounts for a significant proportion of the building industry’s climate impact. The production of the average concrete block emits at least 50% more carbon dioxide than an equivalent ground screw for the same performance. Approximately 8% of the world’s carbon dioxide output can be traced to concrete, and innovative solutions like the ground screw offer a way forward in helping to tackle this problem.

Originally designed in Sweden, the groundscrew was adapted to cope with harsher conditions found in Scandinavia, so are well suited to conditions in the U.S. Each screw is hot-dip galvanized in accordance with ISO 1461 and has added thickness to easily handle the more demanding weather and terrain found in Scandinavia. Since 2012 the success of our ground screws from our ISO 9001 production facilities has gone from strength to strength. Not only are more and more people choosing the ground screw as the right engineering decision, but they are also choosing the right environmental decision.

AUGER ADVANTAGES

Stop Digging’s screws are quick to use and cost effective

By choosing a ground screw, you avoid the hassle of digging and pouring concrete foundations and then wasting time waiting for it to set! The entire process for installing a ground screw takes only a few minutes and you can start using them immediately. With a fast and functional installation you save both time and money and keep your customers happy.

Our ground screws can be mounted in a wide variety of terrain, all year round, come rain, wind or shine. There is no need to postpone work even for a hard frost, as the ground is pre-drilled for each screw to ensure the best possible fixing. Our authorised installers are also experienced with anchoring soundly and securely in everything from sandy soil to rocky ground.

Our ground screws are also environmentally friendly in every way. They produce less carbon than an equivalent concrete foundation, cause less disruption to the ground, and require less plant machinery for digging. Furthermore, our screws are an excellent anchor for temporary buildings and other short term installations as they leave a minimal trace when they are removed. Our dedicated installers can also fix ground screws in hard to reach locations or confined spaces where digging and pouring concrete foundations is just not possible.

ENVIRONMENTAL SUSTAINABILITY

Changing the construction world’s climate impact

Today, the manufacture, transportation and use of concrete accounts for a significant proportion of the building industry’s climate impact. The production of the average concrete block emits at least 50% more carbon dioxide than an equivalent ground screw for the same performance. Approximately 8% of the world’s carbon dioxide output can be traced to concrete, and innovative solutions like the ground screw offer a way forward in helping to tackle this problem.

Originally designed in Sweden, the ground screw was adapted to cope with a much harsher climate and environment than the UK. Each screw is hot-dip galvanized in accordance with ISO 1461 and has added thickness to easily handle the more demanding weather and terrain found in Scandinavia. Since 2012 the success of our ground screws from our ISO 9001 production facilities has gone from strength to strength. Not only are more and more people choosing the ground screw as the right engineering decision, but they are also choosing the right environmental decision.

CONSTRUCTION COMPANY

SKANSKA CHOSES

STOP DIGGING

WHEN SKANSKA BUILT A NEW RESIDENCE IN SOUTHERN SWEDEN, THEY SELECTED STOP DIGGING AFTER A CLOSE TENDERING PROCESS. WE INSTALLED, AMONGST OTHER THINGS, NOISE BARRIERS USING GROUND SCREWS.

Since Stop Digging was founded in 2012, ground screws have become increasingly popular in construction as a robust and long lasting solution for a variety of tasks. Our international customers include Skanska, the world-leading project development and construction group. We worked together on a housing project near Helsingborg in Southern Sweden. Our role was to fasten the extensive sound dampening boards around the development and Patrik Samevall, purchasing manager in northwestern Skåne for Skanska, was pleased with the result, stating:

– “I only have positive things to say. Screws destroy the ground far less compared to going in with large machines and digging and pouring [concrete] at a late stage.”

This was the first time Patrik Samevall had worked with Stop Digging on Skanska project, but probably not the last, as he noted:

– “We will certainly do it again. When the conditions are right, ground screws are a very good solution. The time to install them was short and the total cost was low. Skanska had had their eyes on Stop Digging for a while, and [it was] the Gustavslund project [where] we finally decided to test ground screws”.

– “New products and solutions are always interesting. We had not really thought that ground screws would be suitable for our projects. But there we were wrong.”

WHEN SKANSKA BUILT A NEW RESIDENCE IN SOUTHERN SWEDEN, THEY SELECTED STOP DIGGING AFTER A CLOSE TENDERING PROCESS. WE INSTALLED, AMONGST OTHER THINGS, NOISE BARRIERS USING GROUND SCREWS.

Since Stop Digging was founded in 2012, ground screws have become increasingly popular in construction as a robust and long lasting solution for a variety of tasks. Our international customers include Skanska, the world-leading project development and construction group. We worked together on a housing project near Helsingborg in Southern Sweden. Our role was to fasten the extensive sound dampening boards around the development and Patrik Samevall, purchasing manager in northwestern Skåne for Skanska, was pleased with the result, stating:

– “I only have positive things to say. Screws destroy the ground far less compared to going in with large machines and digging and pouring [concrete] at a late stage.”

This was the first time Patrik Samevall had worked with Stop Digging on Skanska project, but probably not the last, as he noted:

– “We will certainly do it again. When the conditions are right, ground screws are a very good solution. The time to install them was short and the total cost was low. Skanska had had their eyes on Stop Digging for a while, and [it was] the Gustavslund project [where] we finally decided to test ground screws”.

– “New products and solutions are always interesting. We had not really thought that ground screws would be suitable for our projects. But there we were wrong.”

FREQUENTLY ASKED QUESTIONS

Guidance on how,

where, when?

Each building project has its own unique requirements, and our ground screws offer a versatile solution to many of the ground anchoring issues you may face. Here are some general answers to common questions and if you do not find the answer here, please do not hesitate to contact us!

01 Why choose a ground screw?

Stop Digging ground screws provide a stable and secure ground anchor that saves time and money.

Using our screws will make your construction project simpler and easier. If you can avoid concrete, then there is no more having to dig the ground with plant machinery, no need to waste time waiting for it to set and no need to fix the mess caused by the whole laborious process! Ground screws can be installed all year round, even during a hard frost, and can be secured in most types of terrain. Once fitted they can be used immediately for further construction work.

Stop Digging’s ground screws should not be confused with the lightweight ground anchors that can be purchased in DIY outlets. By comparison Stop Digging’s robust ground screws are delivered and installed by our experienced and certified installers – an essential step for an important undertaking such as laying a foundation.

02 Who are Stop Digging’s customers?

We undertake work for both domestic and business projects of any size. All of our installers undergo rigorous training in the use of our specialised equipment and in finding the best solution for you. Whatever the task you have, we have the right solution for you. We have completed projects across the U.S. Stop Digging has grown significantly with 5,000 screws sold in 2012 to 150,000 by 2018. We have set ourselves a goal of 500,000 by 2022.

03 What can a screw support?

Groundscrews can be used as a standard lightweight house foundation, with either timber or steel framing, any kind of transportable building, cabin or container, as well as decking, boardwalks, fences, soundwalls, signposts, solar panel racking, street furniture, playground and outdoor gym equipment. As our fixing is so versatile, we can offer a tailored solution for a wide range of tough tasks – you have a problem – we have the ground screw to help!

04 How deep can a ground screw go?

We use the span tables from NZ3604 to determine quantity of groundscrews needed for a given size of timber bearer. This is the same process for any type of pile foundation. For a typical bearer size of 140x90mm the max span is 1.65m.

So as an example, a free standing deck 8m long by 4m wide would require 3 bearers each with 6 groundscrews, resulting in 18 groundscrews in total. We would ask how high above ground level the deck is proposed to be so we can specify the correct length of groundscrew to achieve this.

05 How long does the ground screw need to be?

This depends on the soil type, load and of course what kind of project it is. We offer four basic models – adapter, pipe, post and beam screw – in a variety of lengths to meet your specific needs. They are especially suited to demanding terrain or locations with complex or historically sensitive structures where intrusive concrete foundations are not suitable. For example, we recently installed foundation screws for a single storey extension of a historic cob and stone house. All of our groundscrews are designed to exceed the requirements of the building code in the U.S.

06 Use in hard or soft ground?

Just as we would pre-drill hard stone for fixing a normal screw, we always drill a pilot hole before installing our ground screw in tricky terrain. This forces smaller stones or gravel aside and our equipment is powerful enough to split medium-sized rocks. If you are building on solid or large enough rocks, our installers can anchor with a drilled steel stud and use ground screws where the ground is more suitable. We offer a complete service with no need to wait for another specialist.

In newly excavated, soft or disturbed soil, our installers are trained to assess the ground and select longer screws if necessary to provide a secure and stable foundation. Our installers are specially trained to select the right screw for your project, install it correctly in whatever terrain they face and finish with the minimum of disruption.

07 How do we install the screw?

We can mount ground screws all year round, even during a cold, hard winter. Our screws were originally developed to cope with the harsher conditions found in Scandinavia, so are well suited to conditions in the U.S., by comparison, is much gentler! Do you want to know more? Feel free to ask your local installer who has a specialist knowledge of your area and useful reference materials.

08 Screw strength?

Our steel ground screws (ISO 630 FE 3604) are specifically developed and adapted to meet the requirements of the Building Code in the U.S. for structural design, and durability. All of our CE marked ground screws are hot-dip galvanized according to ISO 1461 and manufactured by ISO 9001 certified production facilities. They all come with a 25 year warranty.

09 Securing the ground screw?

Just like concrete supports, a ground screw can be affected by the ground settling over time, but they are not generally affected by other forces such as frost heave. Settlement of soil is especially an issue with freshly excavated or disturbed soil and our installers are trained to identify this and select longer screws to provide a deeper, more secure, fixing as needed.

10 How do you calculate the screw load bearing?

We would consult with the architect, designer or structural engineer of the project to confirm design loads of the proposed building or structure. We then are able to specify correct quantity, type and length of groundscrews to create a suitable foundation design.

We use a mixture of our database of in-ground load bearing capacities of our groundscrews, along with on site verification through our approved testing methodology. This onsite testing provides tangible proof of load bearing capacity and confirmation the design loads have been achieved.

Please contact us for more information on the simple process of achieving compliance with the building code.

11 Screw capabilities?

All of our screw models have been rigorously tested to cope with load, pressure and tension bearing and you can read more about our screws here. Our tests were made in normal arable land which we use to calculate the performance of our screws in different soils and terrain. We can test your ground to provide precise feedback for your project planning.

12 Ground screw prices?

We offer a fixed price per installed ground screw. However, our prices vary depending on which screw you need to use and where in the country you are located.

FREQUENTLY ASKED QUESTIONS

Guidance on how,

where, when?

Each building project has its own unique requirements, and our ground screws offer a versatile solution to many of the ground anchoring issues you may face. Here are some general answers to common questions and if you do not find the answer here, please do not hesitate to contact us!

01 Why choose a ground screw?

Stop Digging ground screws provide a stable and secure ground anchor that saves time and money.

Using our screws will make your construction project simpler and easier. If you can avoid concrete, then there is no more having to dig the ground with plant machinery, no need to waste time waiting for it to set and no need to fix the mess caused by the whole laborious process! Ground screws can be installed all year round, even during a hard frost, and can be secured in most types of terrain. Once fitted they can be used immediately for further construction work.

Stop Digging’s ground screws should not be confused with the lightweight ground anchors that can be purchased in DIY outlets. By comparison Stop Digging’s robust ground screws are delivered and installed by our experienced and certified installers – an essential step for an important undertaking such as laying a foundation.

02 Who are Stop Digging’s customers?

We undertake work for both domestic and business projects of any size. All of our installers undergo rigorous training in the use of our specialised equipment and in finding the best solution for you. Whatever the task you have, we have the right solution for you. We have completed projects across the U.S. Stop Digging has grown significantly with 5,000 screws sold in 2012 to 150,000 by 2018. We have set ourselves a goal of 500,000 by 2022.

03 What can a screw support?

Groundscrews can be used as a standard lightweight house foundation, with either timber or steel framing, any kind of transportable building, cabin or container, as well as decking, boardwalks, fences, soundwalls, signposts, solar panel racking, street furniture, playground and outdoor gym equipment. As our fixing is so versatile, we can offer a tailored solution for a wide range of tough tasks – you have a problem – we have the ground screw to help!

04 How deep can a ground screw go?

We use the span tables from NZ3604 to determine quantity of groundscrews needed for a given size of timber bearer. This is the same process for any type of pile foundation. For a typical bearer size of 140x90mm the max span is 1.65m.

So as an example, a free standing deck 8m long by 4m wide would require 3 bearers each with 6 groundscrews, resulting in 18 groundscrews in total. We would ask how high above ground level the deck is proposed to be so we can specify the correct length of groundscrew to achieve this.

05 How long does the ground screw need to be?

This depends on the soil type, load and of course what kind of project it is. We offer four basic models – adapter, pipe, post and beam screw – in a variety of lengths to meet your specific needs. They are especially suited to demanding terrain or locations with complex or historically sensitive structures where intrusive concrete foundations are not suitable. For example, we recently installed foundation screws for a single storey extension of a historic cob and stone house. All of our groundscrews are designed to exceed the requirements of the building code in the U.S.

06 Use in hard or soft ground?

Just as we would pre-drill hard stone for fixing a normal screw, we always drill a pilot hole before installing our ground screw in tricky terrain. This forces smaller stones or gravel aside and our equipment is powerful enough to split medium-sized rocks. If you are building on solid or large enough rocks, our installers can anchor with a drilled steel stud and use ground screws where the ground is more suitable. We offer a complete service with no need to wait for another specialist.

In newly excavated, soft or disturbed soil, our installers are trained to assess the ground and select longer screws if necessary to provide a secure and stable foundation. Our installers are specially trained to select the right screw for your project, install it correctly in whatever terrain they face and finish with the minimum of disruption.

07 How do we install the screw?

We can mount ground screws all year round, even during a cold, hard winter. Our screws were originally developed to cope with the harsher conditions found in Scandinavia, so are well suited to conditions in the U.S, by comparison, is much gentler! Do you want to know more? Feel free to ask your local installer who has a specialist knowledge of your area and useful reference materials.

08 Screw strength?

Our steel ground screws (ISO 630 FE 3604) are specifically developed and adapted to meet the requirements of the Building Code in the U.S. for structural design, and durability. All of our CE marked ground screws are hot-dip galvanized according to ISO 1461 and manufactured by ISO 9001 certified production facilities. They all come with a 25 year warranty.

09 Securing the ground screw?

Just like concrete supports, a ground screw can be affected by the ground settling over time, but they are not generally affected by other forces such as frost heave. Settlement of soil is especially an issue with freshly excavated or disturbed soil and our installers are trained to identify this and select longer screws to provide a deeper, more secure, fixing as needed.

10 How do you calculate the screw load bearing?

We would consult with the architect, designer or structural engineer of the project to confirm design loads of the proposed building or structure. We then are able to specify correct quantity, type and length of groundscrews to create a suitable foundation design.

We use a mixture of our database of in-ground load bearing capacities of our groundscrews, along with on site verification through our approved testing methodology. This onsite testing provides tangible proof of load bearing capacity and confirmation the design loads have been achieved.

Please contact us for more information on the simple process of achieving compliance with the building code.

11 Screw capabilities?

All of our screw models have been rigorously tested to cope with load, pressure and tension bearing and you can read more about our screws here. Our tests were made in normal arable land which we use to calculate the performance of our screws in different soils and terrain. We can test your ground to provide precise feedback for your project planning.

12 Ground screw prices?

We offer a fixed price per installed ground screw. However, our prices vary depending on which screw you need to use and where in the country you are located.

OUR SERVICE

DELIVERING THE SOLUTION

Stop Digging’s experienced installers deliver a reliable, fast and cost effective service, enabling your work to continue without pause. Contact us if you have questions, or would like advice on possible solutions, or to receive a quote and book an installation.

OUR SERVICE

DELIVERING THE SOLUTION

Stop Digging’s experienced installers deliver a reliable, fast and cost effective service, enabling your work to continue without pause. Contact us if you have questions, or would like advice on possible solutions, or to receive a quote and book an installation.

CONTACT ME!

If you would rather have your local installer contact you, leave a message here and we will be in touch shortly.